Introduction

The global energy landscape continues to rely heavily on hydrocarbons, even amid the transition to renewables. Maximizing recovery from existing reservoirs is a critical economic and strategic imperative. Enhanced Oil Recovery (EOR) techniques are essential for this, with chemical EOR (cEOR) playing a pivotal role. Among the arsenal of advanced chemicals, sodium methallyl sulfonate (SMAS) has emerged as a versatile and high-performance monomer and additive, addressing some of the most persistent challenges in modern oil recovery.

Critical Challenges in Modern Oil Recovery

- Harsh Reservoir Conditions: Many remaining oil reserves reside in high-temperature, high-salinity (HTHS) formations. Conventional polymers, like hydrolyzed polyacrylamide (HPAM), degrade under these conditions, losing viscosity and effectiveness.

- Water Channeling and Early Breakthrough: Heterogeneous reservoir formations lead to poor sweep efficiency as injected fluids follow the path of least resistance, bypassing oil-rich zones.

- Chemical Stability and Retention: EOR chemicals must be thermally stable, resistant to mechanical shear, and have low adsorption onto rock surfaces to be cost-effective and propagate deeply into the reservoir.

- Environmental and Operational Compatibility: Chemicals must be compatible with field injection water, often containing divalent ions, and ideally exhibit low toxicity and good biodegradability profiles.

Sodium Methallyl Sulfonate: A Chemical Powerhouse

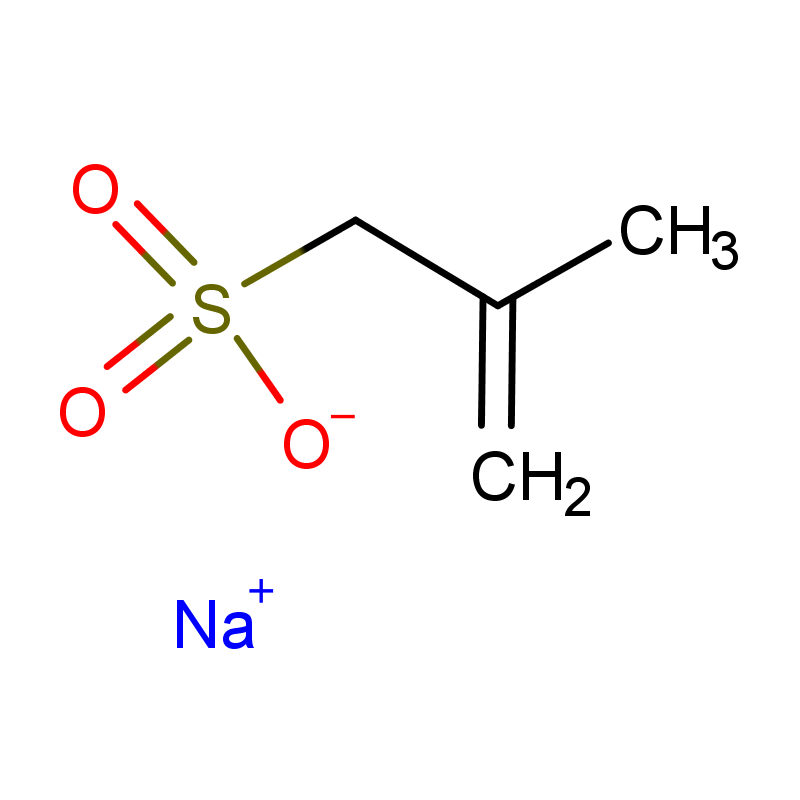

SMAS (CH₂=C(CH₃)CH₂SO₃Na) is a sulfonate-containing vinyl monomer. Its unique molecular structure—featuring a methallyl group and a strongly ionic sulfonate group—imparts exceptional properties ideal for tackling the above challenges.

Key Applications and Mechanisms of Action

1. As a Co-monomer in Thermally Stable Polymers

This is SMAS’s most significant contribution. It is copolymerized with acrylamide (AM) and other monomers to create sulfonated polyacrylamides.

- Addressing HTHS Challenges: The carbon-carbon double bond in the methallyl group is highly stable. The sulfonate group (-SO₃⁻) provides electrostatic repulsion that is far less sensitive to high salinity and hardness than the carboxylate groups (-COO⁻) in standard HPAM. Divalent cations (Ca²⁺, Mg²⁺) cause HPAM to precipitate but have a minimal effect on the sulfonate functionality.

- Result: Polymers incorporating SMAS maintain their viscosity and structure in reservoirs exceeding 90°C and with total dissolved solids (TDS) over 100,000 ppm, dramatically expanding the operational window for polymer flooding.

2. As a Functional Additive in Polymerization

SMAS acts as a chain transfer agent and sulfo-terminator during the polymerization of acrylamide.

- Addressing Shear Sensitivity: This process controls polymer molecular weight and introduces stable sulfonate end groups. These groups reduce polymer chain scission under mechanical shear (e.g., through pumps and well perforations), helping the polymer maintain its viscosifying power post-injection.

3. As a Building Block for Advanced Surfactants

SMAS can be used to synthesize alkyl methallyl sulfonates or other surfactant structures.

- Addressing Interfacial Tension (IFT): These surfactants effectively lower the IFT between oil and water. The strong, salinity-tolerant sulfonate head group ensures effectiveness in harsh brines, aiding in the mobilization of residual oil trapped by capillary forces.

4. As a Scale Inhibitor and Dispersant

The sulfonate group has a strong affinity for inorganic cations.

- Addressing Flow Assurance: SMAS-based polymers can sequester scale-forming ions (e.g., barium, calcium) and disperse fines, preventing formation damage and wellbore scaling that can impede production.

Synergistic Benefits for Reservoir Engineering

The implementation of SMAS-enhanced chemicals provides system-level advantages:

- Improved Sweep Efficiency: Robust, in-situ viscosity leads to better mobility control, diverting flow from thief zones to unswept areas.

- Deep Reservoir Penetration: Low adsorption and high stability allow the chemical slug to propagate uniformly, contacting more of the reservoir volume.

- Extended Project Life: The ability to apply cEOR in more challenging reservoirs unlocks resources previously considered uneconomical.

Environmental and Economic Considerations

SMAS-based polymers, by enabling more efficient oil displacement, reduce the chemical volume and water injection required per barrel of incremental oil. While full life-cycle assessments are necessary, the efficiency gains contribute to a lower environmental footprint per unit of energy recovered. From an economic standpoint, SMAS increases the success rate and ROI of cEOR projects in complex reservoirs.

Conclusion

As the oil industry pushes into more challenging reservoirs, the demand for advanced, robust chemical solutions intensifies. Sodium methallyl sulfonate is not merely an additive; it is a foundational enabler for the next generation of EOR chemicals. By conferring unparalleled salinity tolerance, thermal stability, and mechanical integrity to polymers and surfactants, SMAS directly addresses the core challenges of modern oil recovery. Its integration into chemical formulations is proving to be a critical strategy for sustaining production, improving ultimate recovery rates, and securing energy resources in the 21st century. Future research will likely focus on optimizing SMAS-containing copolymers and developing novel nanostructured or smart fluids for even greater precision in oil mobilization.