Validating the long-term effectiveness of a scale inhibitor like SMAS requires a multi-faceted approach that integrates laboratory testing, sophisticated modeling, and rigorous field monitoring. This process is crucial to de-risk a full-field deployment and ensure economic viability.

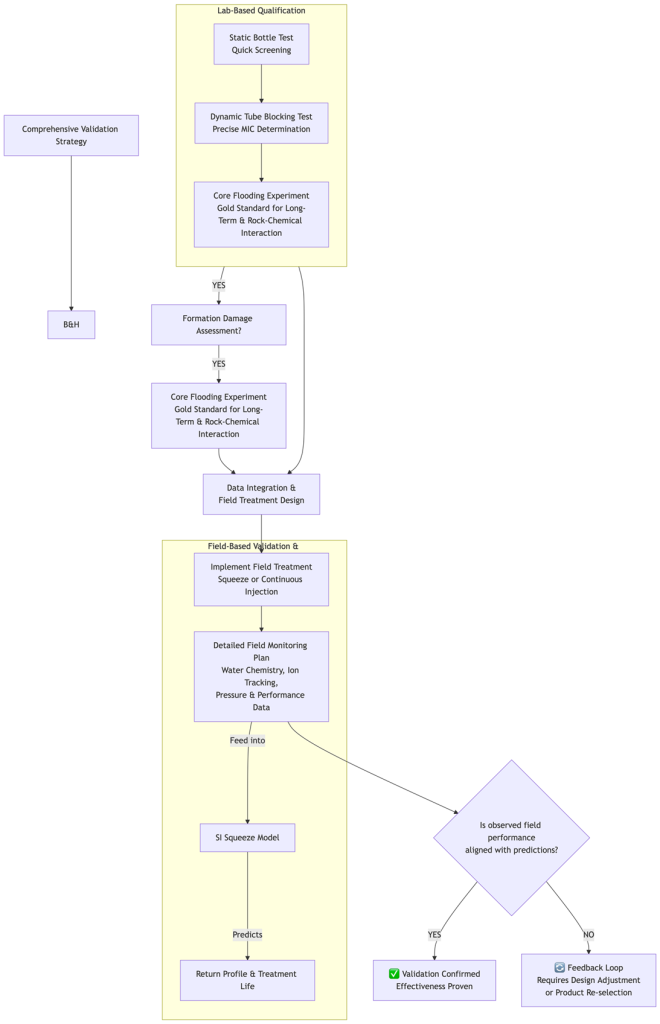

The following chart outlines this comprehensive, multi-stage validation workflow:

Phase 1: Laboratory Validation – Establishing Baseline Efficacy

Before any field application, laboratory tests are essential to confirm SMAS is technically suitable for the specific conditions of your reservoir.

1. Static Inhibition Efficiency Tests (Bottle Tests):

- Purpose: A quick, cost-effective screening method to determine the Minimum Inhibitor Concentration (MIC) and compare the relative performance of SMAS against other inhibitors.

- Procedure:

- Prepare synthetic brines that accurately replicate the formation water (contains Ba²⁺, Sr²⁺, Ca²⁺) and injection water (contains SO₄²⁻) from your target block.

- Mix these brines in the correct ratio in several bottles.

- Add varying concentrations of SMAS to each bottle.

- Place the bottles in a heated bath at the downhole temperature.

- Monitor the solutions over time (e.g., 2, 24, 48 hours) for visual turbidity or use a spectrophotometer to measure absorbance quantitatively.

- Outcome: The lowest concentration of SMAS that prevents scale precipitation for a specified time is identified as the MIC. This is the first critical data point.

2. Dynamic Scale Loop Test (Tube Blocking Test):

- Purpose: A more advanced test that simulates flowing conditions, pressure drop, and nucleation onto a surface. It provides a more accurate and reliable MIC for flowing well conditions.

- Procedure:

- Formation and injection brines are pumped at a controlled ratio through a coiled capillary tube housed in an oven at reservoir temperature.

- SMAS is injected at different concentrations into the brine stream.

- The pressure difference across the coil is monitored in real-time. A sharp increase in pressure indicates scale has formed and blocked the tube.

- Outcome: The precise MIC under dynamic conditions is found. The time it takes for the tube to block at sub-MIC concentrations gives insight into the inhibition kinetics. This test is superior to bottle tests for determining the required inhibitor concentration in the produced water.

3. Core Flooding Experiments – The Gold Standard for Long-Term Validation:

- Purpose: To simulate a scale inhibitor squeeze treatment and evaluate two critical long-term aspects: 1) Adsorption/Retention Release Characteristics: How the inhibitor adsorbs onto the formation rock and how it flows back over time. 2) Formation Damage Potential: Whether the inhibitor or its interaction with brines causes permeability damage to the reservoir rock.

- Procedure:

- A core plug from the target reservoir (or a representative analogue) is saturated with formation brine and installed in a core flooding apparatus under reservoir temperature and confining stress.

- Initial permeability to brine is measured.

- A SMAS solution in a specific “slug” is injected into the core (simulating the squeeze injection).

- The core is shut-in for a period to allow adsorption/retention onto the rock (simulating the soak period).

- The core is then flowed back with synthetic brine(s), and the effluent is collected in small fractions.

- Each fraction is analyzed using ICP-OES or ICP-MS to precisely measure the very low concentrations of SMAS in the return fluid over time (its “return profile”).

- Permeability is measured again after the flood to check for damage.

- Outcome:

- Adsorption Isotherm: Data is used to model how SMAS interacts with the rock, which is crucial for predicting squeeze life.

- Return Curve: Provides a plot of inhibitor concentration vs. pore volumes produced. This shows how long the concentration remains above the MIC determined in earlier tests.

- Squeeze Life Estimate: A preliminary estimate of treatment lifespan is generated.

- Formation Damage Assessment: Confirms whether SMAS is formation-friendly.

Phase 2: Field Application and Monitoring – Proving Real-World Longevity

A successful lab result must be followed by a carefully monitored field trial.

Field Monitoring Plan for a Squeeze Treatment or Continuous Injection:

1. Pre-Treatment Baseline:

- Perform a thorough clean-up of the wellbore to remove existing scale.

- Take multiple, representative water samples for full ion analysis (Ca, Ba, Sr, Mg, Fe, SO₄, etc.) to firmly establish baseline chemistry.

2. Precise Chemical Tracking:

- Inhibitor Residual Analysis: This is the most important monitoring activity. Regularly collect produced water samples (daily initially, then weekly/bi-weekly) and analyze them for the exact concentration of SMAS using a specific technique like HPLC (High-Performance Liquid Chromatography). This allows you to plot its concentration decline over time.

- Ion Tracking: Continuously monitor the key scaling ion pairs (e.g., Barium and Sulfate). A stable ion concentration in the produced water, alongside a decreasing SMAS concentration, is a strong indicator that the inhibitor is working. A sudden drop in barium concentration often indicates that scale is forming despite the treatment (i.e., the SMAS concentration has fallen below the effective MIC).

3. Performance and Indirect Monitoring:

- Downhole Pressure Data: Use downhole pressure gauges (Permanent Downhole Gauges or PDHGs) to monitor the pressure trend. A gradual increase in tubing head pressure or flowing bottomhole pressure, especially when correlated with a drop in SMAS residual below MIC, can signal scale buildup restricting flow.

- Production Performance: Monitor flow rates (oil, water, gas). An unexpected decline could indicate impairment from scale or other issues.

- Wellhead Inspection: Regularly check chokes, valves, and manifolds for signs of scale, as these are primary nucleation points.

4. Data Integration and Modeling:

- Feed the actual field return profile (SMAS concentration vs. time/volume produced) into a squeeze simulation software model.

- Calibrate the model (history match) to the field data. This dramatically improves the accuracy of the model for predicting the long-term squeeze life in subsequent treatments in analogous wells in the same block.

Conclusion: Defining Long-Term Effectiveness

Long-term effectiveness is not just a single number. It is proven when:

- Field MIC is Confirmed: The concentration of SMAS in the produced water, as measured by HPLC, remains above the laboratory-determined MIC for the entire predicted duration.

- Ion Stability is Maintained: The concentrations of scaling ions in the produced water remain stable, showing no loss due to precipitation.

- Well Performance is Stable: No scale-related declines in production rate or increases in pressure are observed.

- Squeeze Life is Predictable: The field-based return profile closely matches the forecast from the calibrated model, validating the understanding of SMAS’s behavior in the specific rock and fluid system of the block.

By following this integrated lab-to-field approach, you can move beyond assumption and conclusively validate whether SMAS will provide effective, long-term scale control in your specific asset.